About Unimax

For 24 years, Unimax has been a dedicated Chinese manufacturer of wood chippers, specializing in tub grinders and horizontal grinders. Leveraging comprehensive capabilities in R&D, manufacturing, and sales, we provide products renowned for their dependable quality and strong customer appeal. Our drive for innovation creates sustained value for partners and fosters industry growth.

Unimax offers a comprehensive range of forestry equipment, including horizontal grinders, tub grinders, brush chippers, and industrial wood chippers. Committed to engineering durability and peak performance, we deliver robust machinery designed to maximize productivity for global clients.

With three strategically located production facilities spanning 120,000 m², our operations integrate state-of-the-art manufacturing technologies. Key equipment encompasses CNC lathes, milling machines, planers, precision drilling systems, automated sawing units, CNC boring machines, dynamic balancing systems, and advanced coiling solutions.

Adhering to a quality-first philosophy, we implement strict quality control protocols at every stage of production, from raw material inspection to final assembly. Our dedication to excellence is validated by ISO 9001 certification and CE compliance, ensuring globally recognized standards for safety and reliability.

By harmonizing innovative engineering with rigorous manufacturing practices, we empower clients to achieve sustainable operational efficiency while reducing lifecycle costs.

- Quality

- Accuracy

- Safety

- Reliance

Why Unimax

Deep Industry Expertise

Focus on wood chippers for 24 years, with a cumulative production of 1,200 wood chippers in 2025, we have accumulated rich and valuable experience in every production step, such as choice of raw material, production process, test, quality control. Precious experience is integrated into every high-quality wood chipper and grinder to continuously create value for customers.

Proven Product Reliability

The wood chipper features a sturdy and durable design, utilizing high-standard components and stringent manufacturing processes. Combined with a three-step inspection procedure, it ensures stable performance even under demanding conditions, thereby reducing downtime and maintenance costs.

Continual Innovation

We actively listen to and analyze customer feedback, transforming real-world challenges into opportunities for improvement. By continuously refining our production processes and advancing design concepts, we deliver wood processing solutions that are higher in quality, more efficient, and increasingly intelligent—helping our customers achieve greater productivity and sustainability.

Comprehensive Technical Support

We ensure optimal customer outcomes through dedicated, end-to-end service:

- Selection & Planning: Expert consultation to match the right equipment to your needs.

- Installation & Commissioning: Professional setup to ensure immediate operational readiness.

- Operation & Training: Comprehensive guidance for safe, efficient, and intelligent use.

- After-sales & Maintenance: Responsive support and parts service to guarantee long-term performance and value.

Quality control

- Research & Developmentwe have a strong research and development team to keep innovation. continuously refine our designs to ensure stringent quality control from the very source.

- Raw materialsPurchase high-quality raw materials and famous brand components such as Cummins engine, SKF bearing according to the design requirements.

- Production processWe utilize advanced CNC equipments to ensure precision and surface quality. Key components undergo heat treatment, like quenching and tempering, to enhance hardness, strength, and wear resistance.

- TestEvery machine passes multiple inspection before leaving the factory, ensuring that only high-quality products are delivered to our customers.

Continue to create value for customers

RESULTS

After 23 years of development, Unimax has grown into a well-known enterprise in China's forestry equipment industry. Our customers are spread over more than 80 countries around the world, and our market share continues to grow. We have been committed to providing customers with efficient forestry crushing solutions.

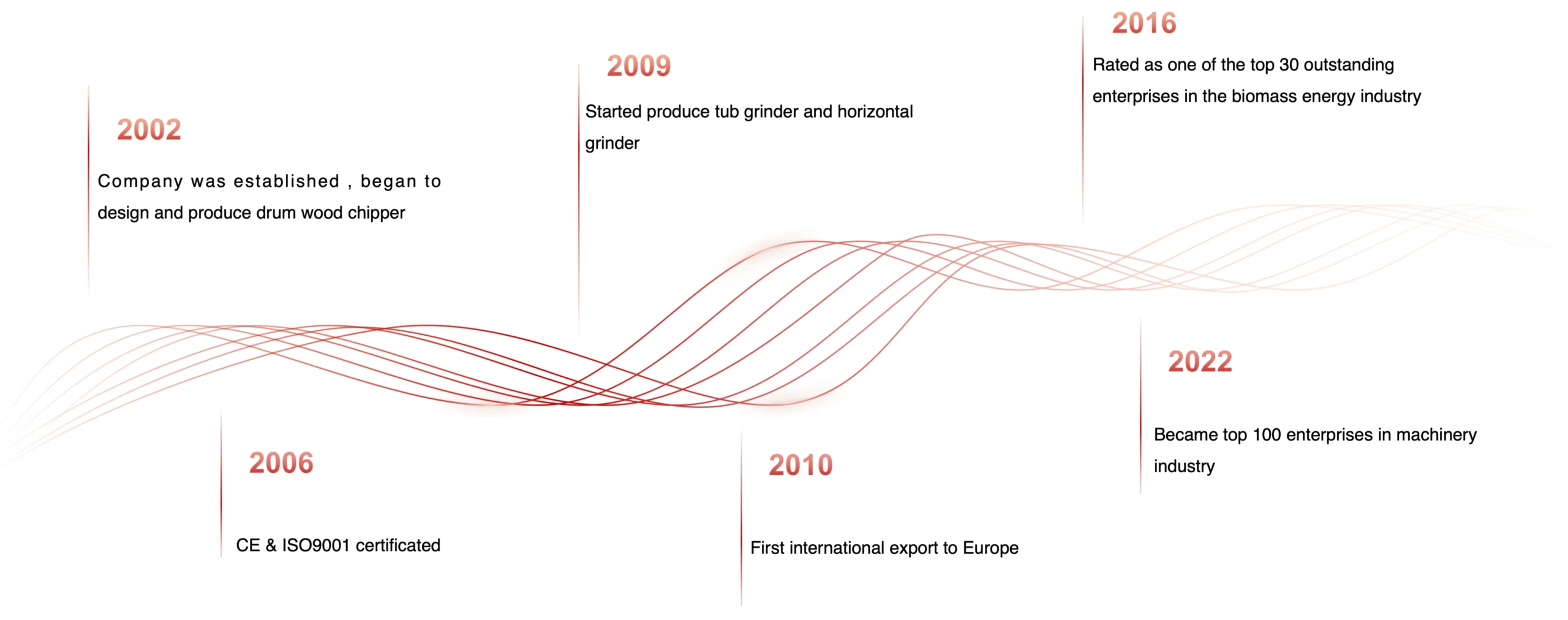

Our history

We are always ready

Our professional team is ready to tailor a crushing solution for you and start a worry-free journey

Of course, tell us your raw materials and uses, we will recommend the most cost -effective equipment. If it is for recycling, our engineers can make a solution for the production line for you.

We are a manufacturer with more than 23 years of experience. We have our own stock workshop, production workshop, assembly workshop, etc. We can provider comprehensive customization and after -sales support. There are no middlemen to earn differences, only lower prices and better support for you.

The factors that affect the life of the tub grinder are generally these, whether the quality of the raw materials is thick and durable, regular maintenance, correct operation of the machine (reduce the wear of the machine), and reasonable working hours. Proper maintenance of the equipment can make the machine last 15-20 years.

Yes, as an agency, you will not only enjoy exclusive agency prices but also receive annual rebates. Additionally, our marketing team will provide you with terminal customer resources in your region.

Of course, in addition to special agent price, the agent can also enjoy the rebate of the year, and our marketing team will also provide you with the customer information in your area.